| ORDER NO | ICB1008 | MATERIAL | MIRCO-TUNGSTEN |

| CUTTING TYPE | BALL NOSE STUD | CUTTING DIAMETER | 1/16 |

| NUMBER OF FLUTE | 2 | FLUTE LENGTH | 1/8 |

| FINISHING COATE | NO | SHANK DIAMETER | 1/8 |

| HELIX ANGLE | 30 | OVER LENGTH | 1-3/4 |

| SHAPE | BALL END | SHANK TYPE | ROUND |

| BRAND | MADE IN TAIWAN | CUTTING TYPE | SINGLE END |

1/16 2 FLUTE BALL NOSE SOLID CARBIDE END MILL

Features

1/16″ 2FLUTE BALL NOSE SOLID CARBIDE END MILL

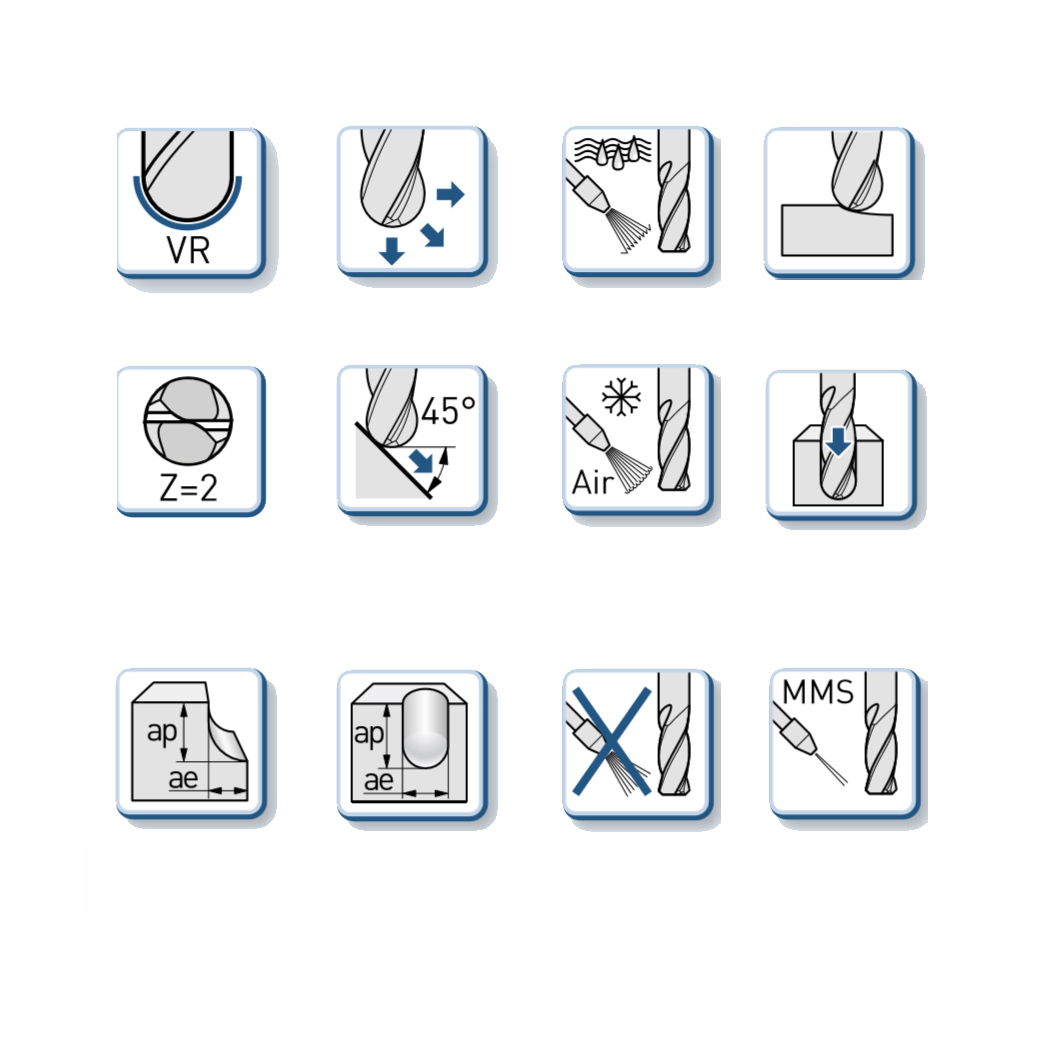

Use: For universal use in different materials (aluminum alloy steel or same class preferred)

Substrate: Submicron carbide grade with excellent T.R.S.

Tool Shank: h5 shank tolerance

Safe-Lock shank for pull out protection and productivity improvement

Chip breaker & evacuation geometry:

Unequal cutting edge angle and helix for vibration reduced machining

Neck for higher cutting depth

Power Mill end mills are fine balanced

Highest run-out accuracy (max. 5 µm)

Cutting diameter h9

Quality:

Consistent high and approved quality

100% cutting output inspection

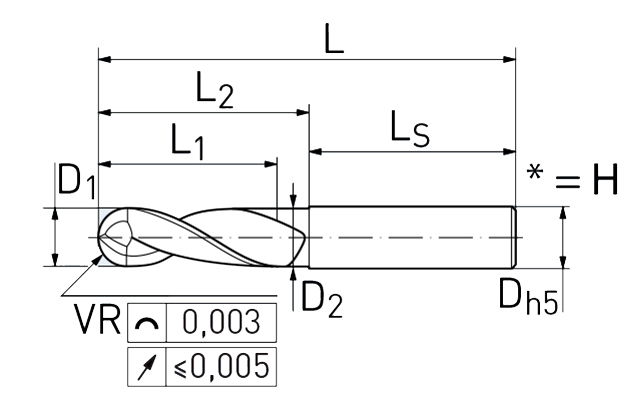

Drawings

Cutting Condition

| Diameter | VC(m/min) | AP(mm) | AE(mm) | FEED (mm/min) | RPM/MIN |

|---|---|---|---|---|---|

| 1/8 | 150 | 0.15 | 0.15 | 2000 | 24000 |

| 3/16 | 226 | 0.17 | 0.17 | 2500 | 18000 |

| 1/4 | 350 | 0.2 | 0.2 | 2800 | 15000 |

| 3/8 | 420 | 0.25 | 0.25 | 3000 | 13000 |

| 1/2 | 450 | 0.3 | 0.3 | 3500 | 8000 |

Related Products

| ORDER NO | D1(MM) | L1(mm) | LS(mm) | D(mm) | L(mm) | TOOTH |

|---|---|---|---|---|---|---|

| ICB001 | 1/8 | 1/8 | 1-1/2 | 1/8 | 1-3/4 | 2 |

| ICB002 | 3/16 | 3/8 | 1-1/2 | 3/16 | 1-3/4 | 2 |

| ICB003 | 1/4 | 3/8 | 1-3/4 | 1/4 | 2-1/2 | 2 |

| ICB004 | 3/8 | 3/4 | 1-3/4 | 1/2 | 2-1/2 | 2 |

| ICB005 | 5/16 | 5/16 | 1-3/4 | 5/16 | 2-1/2 | 2 |

| ICB006 | 1/2 | 3/4 | 1-3/4 | 1/2 | 2-1/2 | 2 |

Tungsten Material Application

The commonly used cemented carbide has WC as the main component bai, and is divided into the following categories according to whether du is added to other carbides:

Tungsten cobalt (WC+Co) hard alloy (YG)

It has high toughness of flexural strength and good thermal conductivity, but has a poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3 and YG6, and its strength and toughness are slightly worse. It is suitable for processing hard cast iron and austenitic stainless steel. , Heat-resistant alloy, hard bronze, etc.

Cutting Condition:

Ionbond provides thin-film coating services and operates, includes PVD, PACVD, CVD, CVA and CVI technologies,

including a broad range of DLC coatings. Please contact us for further information.

We look forward to serving you.